Nifty Alloys Llc

Nifty Alloys Llc UAE Profile

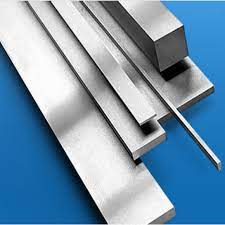

Nifty Alloys LLC started to source and supply, raw materials within the UAE formed in 2020 to supply specialized material to various customers across the Middle East. Nifty Alloys supply a wide range of steel. Combined with a wealth of experience and knowledge, we offer guidance on steel equivalent grades and hard to find steel specifications. While many things have changed in the steel industry our commitment to quality and service remains the same, with our dedication to total customer satisfaction, hoping that bigger is better, we remain a family run business committed to providing a friendly and reliable service. Through our understanding of your Company’s needs for the future, we are able to envision our own. It is this vision, consistent with the evolution of industry, which ensures your confidence in our ability to satisfy the challenges tomorrow will bring,†is our company motto. Quality Control is also involved in the final acceptance and release of material to customers and it is award-winning quality control procedures that have earned business from many prime contractors and government procurement agencies, as well as large and small manufacturing facilities nationally and internationally. We strictly discipline when reviewing the certifications supplied by the mills. This discipline includes access to, and understanding of, a large library of industry and customer specifications, which consist of ASTM, ASME, SAE AMS, Military specifications. Quality Control is involved in the processing of all customer purchase orders and all sales orders to ensure accuracy in all aspects. As a domestic and international specialty metals distributor, our inventory includes, but is not limited to, Aluminum Bronze, Copper Bus Bar, Copper Nickel, Manganese Bronze, Naval Brass, Nickel Based Alloys, High Strength Alloys, Phosphor Bronze, Silicon Bronze, Silicon Iron Bronze, HY80 & HY100 Hot Rolled Steels, and Stainless Steels. We are able to provide quality material due in part to relationships with our partner mill affiliates, which have developed over the past years. The following processes ensure that our customers receive the highest caliber products available: Audits and Inspections of Mill Sources Cause & Corrective Action Document Control and Quality Assurance Records Controlled Handling and Inspection Inventory Re-Test Qualification Material Identification Measuring and Testing Equipment Non-Conforming Material Control Planned Material Audits Traceability to Heat and/or Lot

View Nifty Alloys Llc WebstoreRequest a Quote or More Information from Nifty Alloys Llc

Interested in working with Nifty Alloys Llc? Submit your details below and we’ll connect you directly with the company for quotes, product info, or any questions you may have.

Products and Services from Nifty Alloys Llc

Explore a wide range of products and services offered by Nifty Alloys Llc in UAE. Browse below to learn more and send your enquiries directly.