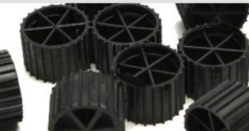

FLOATING MEDIA IN SIO365 MARKETPLACE - PRICE ON REQUEST

POSTED BY : NUTEC OVERSEAS FZE

Category: |

Industrial |

Payment Details: |

Cash/ cheque / pdc |

Floating media can be utilized in new or old bio reactors and enhance performance. Once the media is placed inside a bio reactor and set in proper operation, you have a complete stable, clog-free bio-film reactor.

Microorganisms, which are attached to the floating media reduce the organic load. This is a fixed-film process where the floating media become carriers that build a floating bed in the water(The Bio Film) and stabilize WWTP.

The Bio-Film grows on the bio media surface thet moves along with the water inside the reactor chamber and the floating media carriers the biomass, also known as MBBR = Moving Bed Bio Reactors.

Once submerged inside the bioreactor, the Floating media operates as non-cloggin media. No channels or dead spots like in other technologies. The movement is caused by either aeration, or being mechanically stirred, depending on reactor design and effluent requirements. The Floating media optimizes growth(biomass), and provides shelter and protection for the biomass and makes the WWTP extremely robust and reliable.

The Floating media has been extensively tested and implemented into numerous wastewater plants worldwide. The Floating media has proven to be superior to any known bio media, and can handle pH variation, shock loaidng, cold temperature, and drastically reduce plant size, The AMB Bio Media has proven to stabilize most wastewater plants.

Floating media Represents flexibility and new-engineered potentials in wastewater treatment plant operation. Use in existing tanks, modernize existing system, meet effluent requirements and be in compliance.