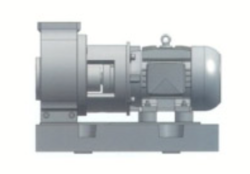

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. In the typical case, the fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits.

Common uses include water, sewage, petroleum and petrochemical pumping. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy.

Centrifugal pumps can be grouped into several types using different criteria such as its design, construction, application, service, compliance with a national or industry standard, etc. Thus one specific pump can belong to different groups and oftentimes this becomes descriptive of the pump itself.

Some of these groups are:

Based on type of volute

Based on nozzle location

Based on orientation of case-split

Based on bearing support

Based on shaft connection to driver

Based on compliance with industry standards

Based on impeller suction

Based on number of impeller/s in the pump

Based on type of volute

GET IN TOUCH - ENQUIRIES

POST YOUR REQUIREMENTS

Other Products From Nutec Overseas FZE

MEMBRANE BIOREACTOR

ULTRAFILTRATION

GREY WATER TREATMENT ...

MARINE SEAWATER DESA ...

REVERSE OSMOSIS SYST ...

PUMPS

AIR OPERATED PUMPS

SILICA GEL WHITE

SILICA GEL

SILICA GEL ORANGE

DESALINATION - RO PL ...

AIR OPERATED DIAPHRA ...

CENTRIFUGAL PUMP PRO ...

CENTRIFUGAL PUMPS

MEDIA FILTRATION

OIL WATER SEPARATOR

ODOR CONTROL SYSTEMS ...

CARBON ADSORPTION SC ...

WATER DISINFECTION

SWIMMING POOL CLEANI ...

CHLORINE TABLET

OZONATOR

CONTAINER DESICCANT

ACTIVATED ALUMINA DE ...

ACTIVATED ALUMINA FL ...

MOLECULAR SIEVE

MOLECULAR SIEVE 3A

MOLECULAR SIEVE 4A

MOLECULAR SIEVE 5A

MOLECULAR SIEVE 13X

FLOWER DRY SILICA GE ...

MOLECULAR SIEVES FOR ...

OIL & GAS EQUIPMENT

MECHANICAL INSTRUMEN ...

ELECTRICAL INSTRUMEN ...

DRILLING EQUIPMENTS

GASKETS

UNDERWATER TOOLS

STRAINERS

PNEUMATIC ROTARY HAM ...

AUTOMATIC SCRAPER ST ...

AIR ELIMINATORS

SUCTION DIFFUSERS

BASKET STRAINERS

DUPLEX STRAINERS

TEE STRAINERS

STRAINER SCREENS AND ...

COARSE BUBBLE DIFFUS ...

FILTER PRESS

AIR OPERATED PUMPS

CENTRIFUGAL PUMPS

POSITIVE DISPLACEMEN ...

SUBMERSIBLE PUMPS

METERING PUMP

FRP PUMPS