Cosmoplast Ind. Co. (l.l.c.)

Want to see Our Products...!

Cosmoplast, a primary member of Group Harwal, has been at the forefront of the plastic industry in the Gulf region since 1976. Since inception, Cosmoplast has been maintaining its leadership position in the region through the company's unwavering emphasis on quality, product innovation and customer focus. The company based in Sharjah, UAE has its operations divided into Pipeline Systems and Moulded Items and Disposable products divisions, which cater to industrial and consumer goods segments respectively.

Under the Pipeline Systems, Cosmoplast manufactures pipes and fittings in sizes ranging from 12 mm up to 2000mm in diameter and caters to an extensive range of market segments and applications covering infrastructure development, plumbing, oil & gas, district cooling, irrigation, landscaping and water extraction. Specialised systems such as pre-insulated pipes, reinforced thermoplastic pipes, specialized plumbing systems and fabricated uPVC and GRP manhole systems are also manufactured by the company. Cosmoplast Pipeline System Division is an ISO 9001:2008 certified unit and assures conformance to many international manufacturing standards including, but not restricted to BS, DIN and ASTM.

The Moulded Items product range include household items, furniture, flower pots, planters, waste bins, KEEPCOLD iceboxes and water coolers, crates, pallets and luggage. The large range of products in various sizes and attractive colours available under these product segments coupled with the comapany's strict adherence to quality, makes Cosmoplast brand an undisputed leader in the consumer plastic products market in the GCC region. The new range of disposable products manufactured primarily with plastic and aluminium include cling films, aluminium foils, aluminium containers, plastic cups, plates, bowls, trays and containers, cutlery, decorative wraps and crystal platters.

Continuously enhancing its capabilities in the field of plastic manufacturing technologies, Cosmoplast employs various processes such as blow moulding, injection moulding, thermoforming, sheet and pipe extrusion to convert a diverse range of polymers such as PVC, polyethylene, cross linked polyethylene, polypropylene, High impact Poly Styrene and glass-reinforced plastic, to name a few.

Its state of the art engineering, design and tool room facilities are fully capable of manufacturing moulds, dies, machinery equipments and other specialized tooling requirements to meet the company's continuous expansion and product development requirements.

Cosmoplast, with its Head Office in Sharjah, UAE, has manufacturing facilities in Sharjah, Abu Dhabi and Dubai converting over 75,000 metric tonnes of plastic per annum. In addition to these, the company also has upcoming facilities in Saudi Arabia and Russia. Cosmoplast has showrooms in Sharjah and Dubai where its complete range of products are displayed.

| Enquiry |

|---|

Products & Services From Cosmoplast Ind. Co. (l.l.c.)

ALUMINUM FOIL

ALUMINUM CONTAINERS

BEVERAGE CUPS

HOT BEVERAGE CUPS

PLATES AND BOWLS

CUTLERY AND STRAWS

GARBAGE BAGS

Videos From Cosmoplast Ind. Co. (l.l.c.)

Top Searches on SIO365

PIPES

AIR CONDITIONING PARTS-CONDENSER COIL MFRS

PREFABRICATED STORAGE UNITS

KINDER GARDEN

SHOTCRETE PUMPS

BATTERY V MOUNT - AWP-7815

TARBOUSH BOX

BUSINESS HUB IN ABU DHABI

PORCELAIN WALLED PLATE

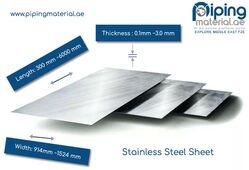

STAINLESS STEEL SHEET

CALCULATOR MJ-120D